What Are The Printing Processes For Customized Packaging Boxes?

What Are The Printing Processes For Customized Packaging Boxes?

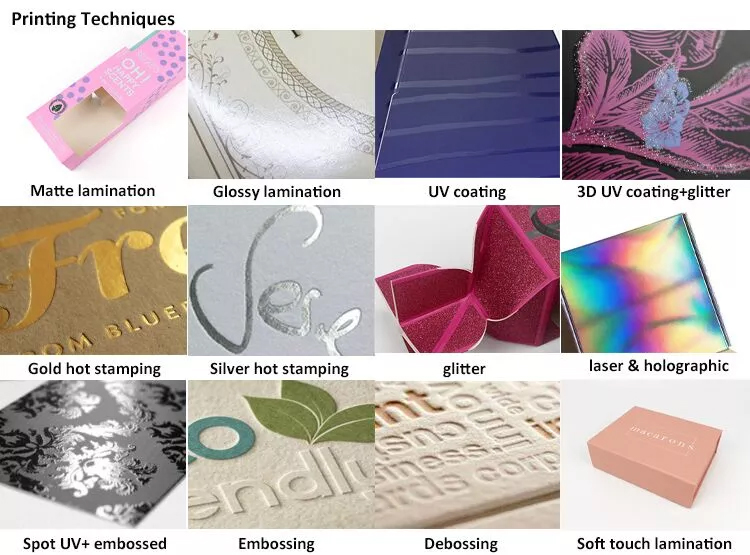

Custom design packaging box printing process for commercial products is the most important purpose of shaping the image of the personality and let customers memorable image, promote products is to seize the customer's attention, dazzling color image can be in the process of readers to interact with print visual arouse their curiosity and attention, but we need to motivate them to buy enthusiasm,This requires further, creative ideas of print surface finishing process strategy.Pay attention to the printing process and surface finishing skills is the most scientific and economic approach, the same quality of products and services because of different packaging reflects the brand and image value of products and services to get value added, and the most important is to achieve these excellent results.So what are the common printing processes?

1.Hot stamping printing process

The performance of bronzing is to heat the required bronzing or silver pattern into a convex version, and then place the desired color of aluminum foil on the printed object. After pressure, the aluminum foil is attached to the printed object.There are many kinds of bronzing paper materials, gold, silver, laser gold, laser silver, black, red, green and so on.The packaging box with gold foil stamping will appear more luxurious and is very suitable for use as a high end gift box in the festive atmosphere.

2. Film covering process

Laminating is a kind of surface processing technology after printing, refers to a product processing technology formed by covering the surface of a transparent plastic film with a laminating machine.After the covered print, the surface will be smoother, brighter, stain-resistant, water-resistant and wear-resistant.The most common use is matter lamination and glossy lamination ,which pay more attention to the tactile feel of the box surface

3, concave and convex embossing process

Concave and convex embossing is the use of relief printing press greater pressure, has been printed on the semi-finished product of the local pattern or text rolled into concave and convex obvious, with a three-dimensional sense of text.Bump embossing technology is mainly used in the post-processing of printed matter and paper containers. In addition to paper packaging box, it is also used in the printing of bottle labels, trademarks, book binding, calendars, greeting cards and other products.

4. UV printing process

UV anti metal etching printing, also known as abrasive or sand surface printing, is in a metal mirror gloss substrate, such as gold, silver paper printed on a layer of uneven translucent ink, after UV curing, similar to the metal surface after etching or abrasive effect.UV anti metal etching ink can produce suede and matte effect, can make the print appear soft and solemn, elegant and showy.

See here, I believe that we have a general understanding of the packaging box printing process. Funsoon packaging specializes in plastic and paper production industry has more than 10 years of experience, have strict control to the quality of the product, the quality of our products is good, if you have need custom printing packaging box with more design ideas, please contact us, we have a professional team for your professional advice and design drawings, looking forward to your enquiry.

Categories

New Blog

© Copyright: 2026 Xiamen Funsoon Packaging Co.,Ltd All Rights Reserved.

IPv6 network supported